- +91-9811302034, 9811282383, 011-41465808

- ssi66@hotmail.com, santronsystemsindia@gmail.com, info@santronindia.in

- 301-302, Vikas Surya Plaza, Commercial Complex, Bl

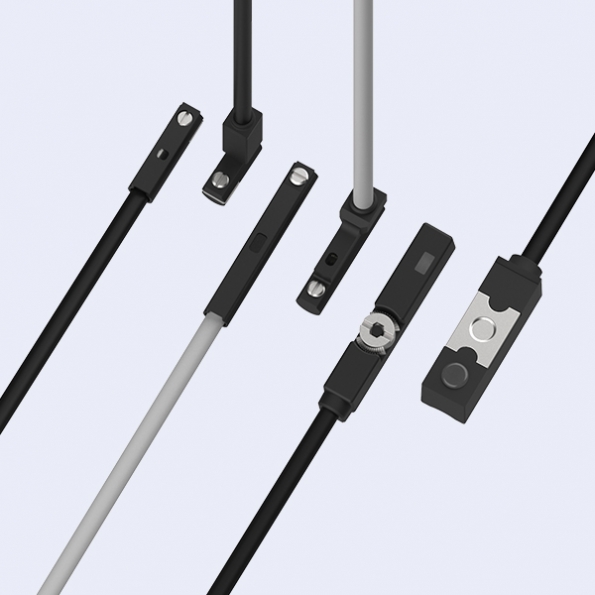

SI Series safety limit switches combine switch and actuator in one device that mounts directly to a machine. The switch is actuated by the presence or movement of a mechanical machine guard and triggers an output when the guard reaches a user-defined switching point.

OUTSTANDING FEATURES

Copyright . All Rights Are Reserved. Website Designed By Websun India.